arenterprises5599@gmail.com - GST NO. : 29APHPB5099L1ZC

- Send Email

Polypropylene Flakes & Granules

Leading Manufacturers, Wholesaler and Trader of Black (A) Grade rPPCP Granules for Industrial/injection Moulding Use, Black (B) Grade rPPCP Granules for Industrial / Injection Moulding Use, Next to Virgin Black PPCP Granules, PP 30% Glass Filled Black Reprocessed Granules, PP 30% Glass Filled Milky White Reprocessed Granules, PP 30% Glass Filled Natural Reprocessed Granules, PPCP Blue Reprocessed Granules, PPCP Dark Grey Reprocessed Granules, PPCP Light Grey Reprocessed Granules, PPCP Red Reprocessed Granules, Royal Blue PP Flakes and Yellow PPCP Flakes from Bangalore.

| Business Type | Manufacturer, Supplier, Trader |

| Color | Deep Black |

| Material | Polypropylene Co-Polymer (Reprocessed, A Grade) |

| Form | Granules |

| Packaging Type | 25 Kg PP Bags |

| Grade | Injection Moulding |

| Impact Strength | High |

| Flow Characteristics | Excellent |

| Surface Finish | Smooth, Uniform |

| Contamination Level | Low |

| Moisture Content | < 0.1% |

PPCP Black A Grade Reprocessed Granules

Superior Finish. Structural Strength. Trusted by Performance-Driven Manufacturers.

When your products demand both form and function, our PPCP Black A Grade Reprocessed Granules deliver. Engineered from clean post-industrial polypropylene co-polymer waste and reprocessed under strict quality controls, these granules offer impact strength, dimensional stability, and a deep black finish—ideal for high-visibility, high-performance applications.

Whether you're producing automotive trims or rugged storage goods, this A-grade reprocessed material provides close-to-virgin performance at a significantly lower cost.

Why Choose Our PPCP A Grade Granules?

A-Grade Reprocessed Quality – Virgin-like behavior for high-performance needs

Deep, Uniform Black Colour – Ideal for visible components and final-use surfaces

High Impact Resistance – Withstands mechanical stress and daily wear

Excellent Mouldability & Flow – Improves cycle time and product consistency

Batch Consistency – Dust-free, moisture-controlled, and extrusion/injection-ready

Ideal Applications:

Automotive Interiors & Trim Panels

Industrial Crates, Bins & Pallets

Furniture Components & Structural Plastics

Tool Casings, Panels, and Enclosures

Consumer Goods Requiring Strength & Appearance

| Business Type | Manufacturer, Supplier, Trader |

| Color | Black |

| Application | Injection Moulding For Crates, Containers, Panels, Household Items, Etc. |

| Type | Reprocessed Granules |

| Material | PPCP |

| Key Benefits | Stable Flow Properties, Cost Optimization, Maintains Visual Appeal |

| Best Fit For | Plastic Component Manufacturers, Traders, Compounders, OEMs Producing Medium-duty Utility Plastics |

| Problem It Solves | Reduces Raw Material Cost Without Compromising Basic Strength |

PPCP Black (B) Grade Reprocessed Granules – Reliable Performance, Smarter Cost

Our PPCP Black (B) Grade Reprocessed Granules are the perfect choice for manufacturers who prioritize functionality and affordability. Sourced from premium post-industrial polypropylene copolymer waste and reprocessed using advanced extrusion techniques, these granules offer good impact resistance, dimensional stability, and consistent moldability—ideal for non-critical, medium-duty applications.

Key Advantages:

Engineered for Injection Moulding – Ideal for crates, containers, panels, household items, and utility products

Stable Flow Properties – Smooth, hassle-free processing on standard injection machines

Uniform Black Colour – Enhances appearance without additional color correction

Cost-Effective Solution – Reduces raw material expenses while maintaining functional strength

Best For:

Plastic component manufacturers

Compounders and traders seeking value-grade alternatives

OEMs producing medium-duty utility plastic products

Problem It Solves:

When A-grade material is overkill, our B-grade PPCP granules deliver dependable quality at a lower price point—perfect for high-volume, cost-sensitive projects where performance still matters.

| Business Type | Manufacturer, Supplier, Trader |

| Material | Polypropylene |

| Color | Black |

| Application | Automotive Interiors,Household Plastics,Electrical & Appliance Casings,Furniture Components,General Injection Molded Goods,Pipe Making |

| Type | Reprocessed Pp Granules |

| Grade | Next-to-Virgin |

| Finish | Premium |

| Properties | High Tensile Strength, Flexibility, Gloss |

| Molding Flow | Smooth |

| Ash Content | Low |

| Odor | Odor-Free |

| Cost Savings | 20-40% Vs. Virgin PP |

| Consistency | Batch-to-Batch |

| Sustainability | Supports Green Sourcing |

Premium Finish. Virgin-Like Performance. Smart Savings.

PP Black Reprocessed Granules – Next-to-Virgin Grade

When your production line demands high visual appeal, mechanical reliability, and smooth processing—without the cost of virgin polymer—our Next-to-Virgin PP Black Granules are the ideal fit.

Sourced from clean post-industrial material and processed through fine filtration, these granules mirror virgin polypropylene in strength, color, and finish, making them ideal for visible parts and consumer-grade products.

Why Choose This Grade?

Jet Black Finish – Rich, uniform tone for aesthetic surfaces

Next-to-Virgin Properties – Retains high tensile strength, flexibility & gloss

Smooth Molding Flow – Excellent surface finish, minimal sink marks or warping

Low Ash, Odor-Free, Clean Material – Hassle-free for high-speed lines

Masterbatch Compatible – Mixes cleanly for tinted or custom applications

Applications

Automotive Interiors – Panels, trims, and non-safety fittings

Household Plastics – Buckets, organizers, storage bins

Electrical & Appliance Casings – Fans, adapters, remote shells

Furniture Components – Chair seats, armrests, handles

General Injection Molded Goods – Toolboxes, trays, storage solutions

Why Processors Trust This Grade

Cuts Material Cost by 20–40% vs. Virgin PP

Batch-to-Batch Consistency – Controlled MFI, color & strength

Sustainable Choice – Diverts industrial waste, supports green sourcing

Trusted by OEMs Nationwide – Used across India and export markets

| Business Type | Manufacturer, Supplier, Trader |

| Material | Polypropylene With 30% Glass Fiber |

| Color | Black |

| Country of Origin | Made In India |

| Recycled | Yes |

| Type | Reprocessed Granules |

| Key Features | 30% Glass Fiber Reinforced - Superior Strength,Heat & Chemical Resistant - Performs In High Temperatures,Dimensional Stability - Reduced Shrinkage,Economical & Sustainable - Substitute For Virgin Material,Smooth Processing - Uniform Granule Size |

| Application | Automotive - Brackets, Under-hood Parts,Electrical - Durable Casings,Industrial - Machine Covers,Appliances & Furniture - Handles, Fittings,Structural Components, High-stress Applications |

Engineered Strength. Reinforced for Demanding Applications

PP 30% Glass-Filled Black Reprocessed Granules

Designed for structural durability and dimensional reliability, AR Enterprises' PP 30% GF Black Granules are reprocessed engineering-grade materials ideal for high-stress components. Reinforced with 30% glass fiber, they offer enhanced rigidity, reduced warping, and outstanding cost-efficiency—without compromising on mechanical performance.

The Manufacturing Challenge

Virgin glass-filled polypropylene is costly and often excessive for non-load-critical components. Meanwhile, inconsistent recyclates can cause process instability or structural failure.

Our Solution

Our reprocessed PP GF30 black granules are sourced from clean post-industrial waste and optimized for injection molding, extrusion, and technical-grade part manufacturing.

Key Product Features

30% Glass Fiber Reinforced – Superior tensile, flexural, and impact strength

Heat & Chemical Resistant – Performs in elevated temperature conditions

Dimensional Stability – Reduced shrinkage and improved molding precision

Economical & Sustainable – Ideal substitute for virgin GF polypropylene

Smooth Processing – Uniform granule size for optimized flow and cycle times

Recommended Applications

Perfect for manufacturers in:

Automotive – Brackets, under-hood parts, dashboard supports

Electrical – Durable casings, housing components

Industrial – Machine covers, rigid panels, enclosures

Appliances & Furniture – Handles, fittings, base frames

Why Top Buyers Choose This Product

Reliable Consistency – Batch-tested for process and performance quality

Cost Savings – Significant price advantage over virgin PP GF30

Eco-Conscious Choice – Reprocessed, landfill-diverting input

Trusted by OEMs & Compounders – For structural applications needing high repeatability

Build with Strength. Mold with Confidence.

Choose AR Enterprises’ PP GF30 Black Reprocessed Granules for engineering-grade performance at an economical and sustainable price.

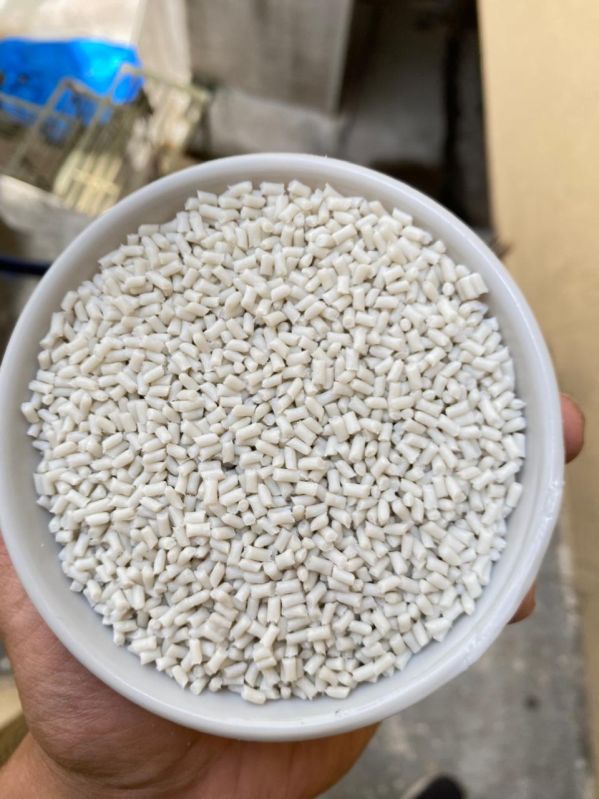

| Business Type | Manufacturer, Supplier, Trader |

| Color | White |

| Packaging Type | 25 Kg PP Bags |

| Form | Uniform Cut Granules |

| Material Composition | Polypropylene + 30% Glass Fiber (Recycled) |

| Reinforcement | 30% Glass Fiber (Verified) |

| Processing Method | Injection Moulding |

| Ash Content | Controlled & Clean |

| Thermal Stability | High - Suitable For Elevated Temperature Use |

| Tensile Strength | High - For Load-bearing Components |

| Shrinkage / | Stable - Precision-fit In Moulded Parts |

PPGF 30% Natural Reprocessed Granules

– High Strength. Heat Resistant. Cost Optimized.

PPGF 30% Natural R/P Granules are an engineering-grade compound made from Polypropylene reinforced with 30% Glass Fiber, designed for structural strength, thermal stability, and stiffness in high-performance moulding applications. This reprocessed grade offers a cost-effective alternative to virgin PPGF 30%, without compromising on reliability or consistency.

Common Buyer Challenges:

Virgin PPGF 30% is too expensive for cost-sensitive projects

Recycled variants often lack true glass content or flow consistency

Shrinkage, warpage, and weak parts due to inferior quality inputs

Why Our PPGF 30% Natural R/P Granules Work:

True 30% Glass Fiber Reinforcement – Verified and quality checked

High Dimensional Accuracy – Reduced warpage and shrinkage

Superior Mechanical Strength – Maintains integrity under load

Injection Moulding Friendly – Clean, clog-free flow

Heat & Impact Resistant – Suitable for engine bay and electrical parts

Lower Cost per Part – Ideal for scaling production efficiently

Recommended Applications: 🔧 Automotive Components

Fan housings, dashboards

Battery casings, bumpers

⚡ Electrical / Electronics

Fuse boxes, plug housings

Appliance parts and connectors

🧰 Industrial & Engineering

Enclosures, gears, brackets

Tool handles, load-bearing supports

🪑 Consumer Goods

Luggage frames, seating components

Structural handles and frames

| Business Type | Manufacturer, Supplier, Trader |

| Color | Natural (Off-white) |

| Packaging Type | 25 Kg PP Bags |

| Form | Uniform Cut Granules |

| Tensile Strength | High - Load-bearing Parts |

| Material Type | PP + 30% Glass Fiber (Reprocessed) |

| Reinforcement | 30% Glass Fiber |

| Processing Method | Injection Moulding |

| Ash Content | Controlled & Clean |

| Thermal Stability | High - Under-the-hood Use |

| Dimensional Accuracy | Stable - Low Shrinkage & Warpage |

PPGF 30% Natural Reprocessed Granules – Performance-Driven. Budget-Smart.

PPGF 30% Natural R/P Granules are a glass fiber-reinforced polypropylene (PP) compound, engineered for strength, stiffness, and thermal stability in demanding applications—all while reducing your raw material costs.

Blended with 30% glass fiber (verified) and reprocessed under strict quality control, this material is the smart choice for manufacturers who need precision, reliability, and durability without paying a premium for virgin PPGF.

Why Most Buyers Struggle:

Virgin PPGF 30% is too expensive for mid-to-high volume projects

Recycled grades often lack true reinforcement, leading to poor performance

Inconsistent shrinkage, warpage, or flow issues cause high rejection rates

Why Our Material Works:

✅ True 30% Glass Fiber Reinforcement – Tested and guaranteed

✅ Dimensional Stability & Shrinkage Control – Perfect for high-precision moulds

✅ Superior Mechanical Properties – High tensile strength and rigidity

✅ Clean, Stable Processing – Compatible with standard injection moulding machines

✅ Excellent Thermal Resistance – Suitable for engine bay and electrical applications

✅ Cost-Effective – Delivers virgin-like performance at a reduced cost

Applications:

Automotive:

Fan housings

Battery casings

Bumper structures

Dashboard components

Electrical & Electronics:

Plug & fuse housings

Appliance interiors

Cable holders

Industrial Use:

Tool handles

Gear housings

Enclosures & brackets

Consumer Goods:

Trolley/luggage components

Chair backs and seating parts

Structural handles and frames

| Business Type | Manufacturer, Supplier, Trader |

| Material | Polypropylene |

| Color | Royal Blue |

| Condition | Reprocessed |

| Type | Reprocessed Granules |

| Country of Origin | India |

| Grade | Injection & Extrusion Grade |

| Key Features | Royal Blue Finish - Uniform, Bright Color For Visible Plastic Goods,Good Impact Strength & Flexibility - Durable For Household And Industrial Use,Injection & Extrusion Compatible - Smooth Flow, Minimal Warping Or Sink Marks,Filtered & Dust-Free - Reduces |

| Popular Applications | Furniture Parts - Chairs, Arms, Handles,Household Items - Buckets, Baskets, Kitchenware,Plastic Crates & Boxes - Storage And Transport Bins,Automotive Non-Critical Parts - Trims, Interior Fasteners,Industrial Packaging - Containers, Pallets, Trays |

PP Blue Reprocessed Granules – Royal Blue | Injection & Extrusion Grade

In industries where color consistency, material reliability, and cost control are critical, our PP Blue Reprocessed Granules deliver a trusted solution.

Crafted from clean, post-industrial polypropylene, these granules are designed to run efficiently on high-speed machines with minimal waste and maximum repeatability.

Key Features

Royal Blue Finish – Uniform, bright color for visible plastic goods

Good Impact Strength & Flexibility – Durable for household and industrial use

Injection & Extrusion Compatible – Smooth flow, minimal warping or sink marks

Filtered & Dust-Free – Reduces equipment wear and improves surface finish

Economical & Scalable – Ideal for bulk buyers without compromising quality

Popular Applications

Furniture Parts – Chairs, arms, handles

Household Items – Buckets, baskets, kitchenware

Plastic Crates & Boxes – Storage and transport bins

Automotive Non-Critical Parts – Trims, interior fasteners

Industrial Packaging – Containers, pallets, trays

Why Choose This Grade?

Batch Consistency for High-Speed Lines

Eco-Conscious Sourcing from Industrial PP Waste

Versatile for Custom Moulding or Blending

Preferred by Indian Processors & OEMs

Engineered for Reliability. Priced for Scale. Trusted by Manufacturers.

Choose our PP Blue R/P Granules when your production needs consistent performance — without overspending on virgin polymer.

| Business Type | Manufacturer, Supplier, Trader |

| Application | Crates,Bins,And Industrial Pallets,Furniture Components,Medium-duty Utility Products,Injection Moulding And Extrusion Processes |

| Color | Dark Grey |

| Material | PPCP (Polypropylene Co-Polymer) |

| Type | Reprocessed Granules |

| Country of Origin | India |

| Packaging Size | 25 Kg |

| Form | Granules |

| Condition | Reprocessed |

PPCP Dark Grey Reprocessed Granules – Strength You Can Mold

Our PPCP (Polypropylene Co-Polymer) Dark Grey Reprocessed Granules are engineered for manufacturers seeking a balance of strength, impact resistance, and cost-efficiency. Made from carefully sourced industrial-grade PP scrap, these granules are filtered, moisture-free, and ready for injection moulding and extrusion processes.

Whether you’re producing crates, furniture parts, or industrial containers, these granules offer reliable structural integrity and consistent finish—cycle after cycle.

Why Choose Our Granules?

🔧 Consistent Mold Flow – Reduces rejections and tool wear

🛡️ Strong Impact Resistance – Durable enough for demanding applications

🎨 Uniform Dark Grey Shade – Ensures visual consistency across products

💰 Cost-Effective for Bulk Production – Great value for utility and semi-engineering components

🧼 Clean & Dust-Free – Machine-friendly and ready for use

Applications:

Crates, bins, and industrial pallets

Furniture components

Electrical enclosures and housings

Automotive interiors (non-critical)

Medium-duty utility products

Solving the Real Issue:

Inconsistent recycled PPCP can cause poor flow, cracks, or downtime. Our batch-stable PPCP granules are optimized for smooth operation, strength, and consistent performance—helping you reduce rejections and maximize output.

| Business Type | Manufacturer, Supplier, Trader |

| Packaging Size | 25 Kg |

| Form | Granules |

| Application | Crates,Bins,Household Goods,Chairs,Etc.,Medium-duty,Non-load-bearing Products |

| Color | Light Grey |

| Material | Polypropylene Co-Polymer (Reprocessed) |

| Grade | Injection Moulding |

| Melt Flow Index (MFI) | Medium (Customizable) |

| Impact Resistance | High |

| Moisture Content | < 0.1% (Filtered & Dried) |

| Processing Methods | Injection Moulding, Extrusion |

| Finish | Smooth, Uniform Tone |

PPCP Light Grey Reprocessed Granules – Toughness Meets Cost-Efficiency

When your production line demands durability, consistency, and savings, our PPCP Light Grey R/P Granules are up to the task—delivering reliable performance across every cycle.

Crafted from high-grade post-industrial polypropylene co-polymer scrap and reprocessed under stringent quality controls, these granules offer stable melt flow, excellent surface finish, and strong mechanical properties—making them a go-to material for general-purpose and industrial-grade injection moulding.

Your Challenge:

Inconsistent recycled PPCP often causes:

High rejection rates

Poor surface finish

Shrinkage and warping

Costly mould/tool wear

Our Promise:

We deliver machine-friendly, batch-consistent granules that ensure:

Low shrinkage & high dimensional stability

Uniform light grey tone

Moisture-free & filtered feedstock

Smooth flow and better part formation

Applications:

Crates, bins, and storage boxes

Household utility plastic goods

Industrial components and panels

Chair backs, seats, and molded parts

General-purpose plastic products

Why Choose This Grade?

✅ Uniform Light Grey Shade – Great for utility or semi-premium applications

✅ High Impact Strength – Built to withstand stress and handling

✅ Excellent Dimensional Stability – Ensures consistent mold fill and part shape

✅ Virgin Substitute – Strong enough for many non-critical applications

✅ Clean & Filtered – Low tool wear and smoother machine operation

| Business Type | Manufacturer, Supplier, Trader |

| Material | Polypropylene |

| Color | Red |

| Condition | Reprocessed |

| Application | Injection Moulding, Pipes, Injection Molding,Extrusion |

| Packaging Size | 25 Kg |

| Type | Reprocessed Pp Granules |

| Country of Origin | India |

PP Red Reprocessed Granules – High-Performance, Cost-Efficient Polymer Solution

Our PP Red Reprocessed Granules are engineered for manufacturers seeking a vibrant, uniform red color combined with dependable mechanical strength. Ideal for general-purpose and industrial-grade applications, these granules deliver consistent quality at a fraction of the cost of virgin materials.

Key Features:

Rich, Uniform Red Shade – Enhances product aesthetics and consumer appeal

Smooth Injection Performance – Reduced rejections, excellent surface finish

Durable Physical Properties – Reliable tensile and flexural strength for demanding uses

Cost-Efficient & Eco-Friendly – Sustainable choice for bulk manufacturing

Dust-Free, Filtered Quality – Ready for direct use in moulding operations

Applications:

Consumer utility items

Industrial storage and transport products

Furniture components

Automotive interiors (non-critical)

General injection-moulded plastic parts

Whether you're replacing red masterbatch or sourcing dependable recycled PP, our PP Red R/P Granules offer a balance of quality, appearance, and affordability—ideal for scalable, eco-conscious production.

| Business Type | Manufacturer, Supplier, Trader |

| Color | Royal Blue |

| Application | Plastic Crates,Bins,Household Items,Auto Interior Components,Storage Products,Hangers,Utility And Hardware Plastic Items,Injection Moulding Application |

| Type | Plastic Flakes |

| Material | 100% Post-Industrial Recycled Polypropylene (PP) |

| Grade | Injection Moulding |

| Packaging Type | 25kgs |

PP Royal Blue Flakes – Clean, Consistent & Cost-Effective for Injection Moulding

Our PP Royal Blue Flakes offer a reliable, budget-friendly alternative to virgin polypropylene for injection moulding applications. Sourced from premium post-industrial PP scrap, these flakes are washed, color-sorted, and uniformly crushed to ensure optimal performance and minimal contamination.

Common Issues, Solved:

Tired of paying high prices for virgin PP?

Struggling with poor-quality recycled material that clogs machines and compromises product quality?

Facing color inconsistency or unwanted impurities?

Our Royal Blue PP Flakes are engineered to overcome these challenges.

Key Features:

Clean & Low-Dust Flakes – Reduces machine wear and downtime

Consistent Royal Blue Color – Minimizes or eliminates the need for masterbatch

Good Melt Flow & Bonding – Ensures smooth, trouble-free processing

Injection Moulding Grade – Perfect for general-use plastic items

Applications:

Plastic crates, bins, and storage solutions

Buckets, tubs, containers, and household utilities

Non-critical automotive interior parts

Hangers, hardware plastics, and general-use moulded items

Specifications:

Color: Royal Blue

Material Type: Post-industrial Recycled PP

Grade: Injection Moulding

| Business Type | Manufacturer, Supplier, Trader |

| Color | Bright Yellow |

| Form | Uniform Crushed Flakes |

| Packaging Type | 25 Kg Bags |

| Grade | Injection Moulding |

| Impact Strength | Good (Non-load-bearing) |

| Contamination | Controlled |

| Moisture Content | < 0.1% (Washed & Dried) |

| Processing Method | Injection Moulding |

PPCP Yellow Flakes – Clean, Cost-Efficient, Injection-Grade

Looking for a reliable, cost-effective raw material for injection moulding? Our PPCP Yellow Recycled Flakes are the smart choice for manufacturers who need performance without overpaying for virgin material.

Made from clean post-industrial polypropylene co-polymer waste, these flakes are washed, color-sorted, and uniformly crushed to ensure smooth processing and strong end-product quality. Whether you’re moulding buckets, crates, chairs, or non-critical auto parts, these flakes deliver consistent results—cycle after cycle.

Why Manufacturers Choose These Flakes:

💪 Good Impact Strength – Durable for everyday plastic products

⚙️ Injection-Friendly Flow – Works well on standard machines

🧼 Clean & Consistent Quality – Low dust, minimal contamination

💰 Cost-Efficient – Ideal substitute for virgin PPCP

🌍 Eco-Conscious – Supports recycling and reduces plastic waste

Common Applications:

Household goods: Buckets, tubs, bins

Industrial moulded items: Crates, trays, panels

Furniture parts: Chairs, seat backs

Non-critical automotive interior components

Utility and general-use plastic items